The Best Tools for Monitoring Your 3D Prints

June 08, 2023

Your Own Eyes and Ears

I like to monitor my 3D prints closely. You can learn so much by just watching and listening to a 3D printer in action. The more closely you look and listen, the more you'll see and hear!

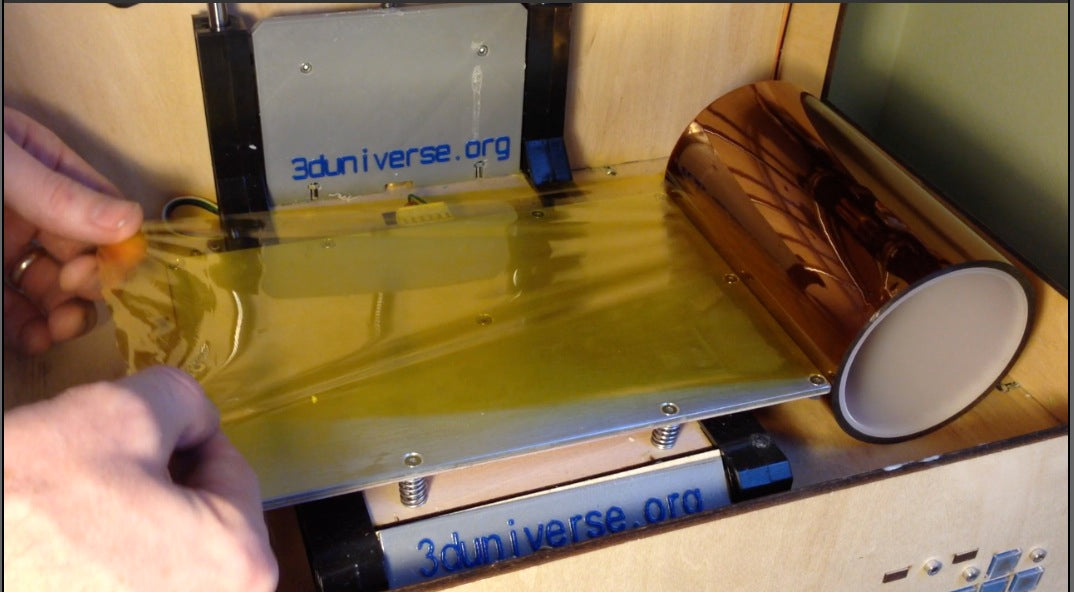

For example, watching is especially important for the first layer of a print. I watch the first layer carefully to make sure the bed is perfectly leveled and the extruded plastic is being pressed flat into the build plate.

I watch to ensure there's good adhesion to the build plate, especially at the edges of the print. If any of the edges are lifting off the build plate, it's likely to get worse and lift more as the print proceeds. This is especially true with ABS prints.

Here's an excellent guide for visually troubleshooting issues with 3D prints. This is written for the Ultimaker 2 specifically, but much of the information is also applicable to other desktop 3D printers.

So there's a lot we can see by watching carefully. But there's also a lot we can "see" from careful listening! After watching the first layer, I find that I can detect some of the most common print issues by sound more readily than by sight.

Each printer has a very distinct sound that it makes when everything is working properly. It's important to become very familiar with that sound, so you can detect even the slightest variations.

One of the most common examples of an issue would be a sort of clicking sound that can start to occur when there are problems feeding the filament. This can be caused by a filament jam, or when the printer is being asked to extrude material faster than it can be melted and pushed out of the nozzle.

Catching this kind of issue quickly can mean the difference between a good print and a failed print since you can pause the print job to reload the filament, or adjust flow settings before it causes any serious problems.

If you start to hear a squeaking sound as the extruder moves around, that can indicate that it's time to apply some lubricant to the appropriate parts of the printer, which varies by printer type.

If your extruder is instructed to move somewhere beyond the X/Y boundaries of the print bed, it can result in a loud grinding noise as the belts slip when the extruder reaches the limit of its range of movement.

These are just a few examples, but the basic idea is the same. Become very familiar with the way your printer looks and sounds when it's working properly, and it will become much easier to identify exactly what's going on when something does inevitably go wrong.

More 3D Universe blog posts:

Check Out Our Review of Simplify3D V2.0.1 HERE.

Learn about e-NABLE, the global volunteer community that's 3D printing limbs for people in need HERE.