3D Printing in the Automotive Industry

June 08, 2023

The automotive industry is ripe for the adoption of 3D printing technology which has already been proven beneficial in other industries. The potential for cost savings in the automotive sector is significant.

3D printing technology can be used to create prototypes and production parts for vehicles and is a fast and efficient way to create end-use parts at a fraction of the cost of traditional manufacturing methods.

Weight Savings with 3D Printed Parts for Cost and the Environment

The use of 3D printing technology in the automotive industry can lead to significant weight savings in the vehicles that are being produced, which can ultimately lead to improved fuel efficiency. This is because 3D-printed parts can be made with very precise tolerances, which means that less material is needed to create them.

In addition, 3D printed parts can be made with complex shapes in a variety of materials that would be impossible to create using traditional manufacturing methods. This means that parts can be made lighter and stronger, which leads to further weight savings. To top it off, these parts can be made from environmentally friendly materials that are also recyclable.

The potential for cost savings and weight reduction make 3D printing technology a compelling option for the automotive industry. It is an exciting new technology that has the potential to revolutionize the way cars are made as well as make a significant improvement to our environment.

3D Printing vs. Tooling Parts

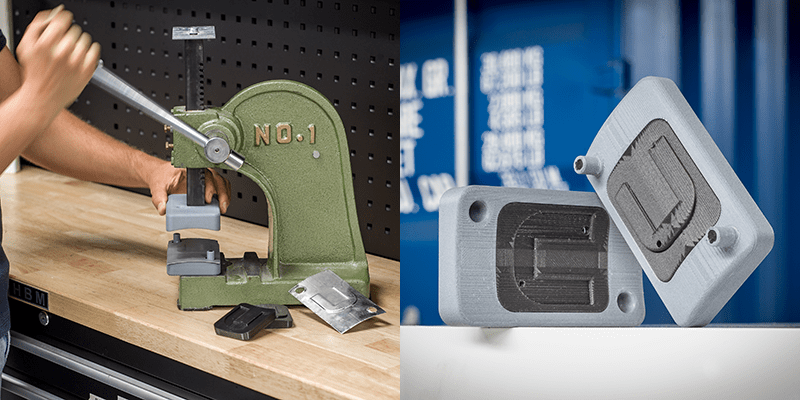

One of the main ways in which 3D printing saves money in the automotive industry is in the area of tooling. With traditional methods, the tooling required for a new part or prototype can be extremely expensive. With 3D printing, however, the tooling can be produced much more quickly and cheaply. This means that companies can bring new products to market much faster and with less investment.

For example, some companies use 3D printers to create prototypes or small batches of parts. This can be helpful for companies who want to test a new design before investing in the tooling necessary to mass produce it.

3D Printing Custom Parts in the Automotive Industry

With the use of 3D printing, car parts can be created with custom and intricate designs, which can make cars more stylish and unique. Using this technology can help automakers keep up with the latest trends and technologies, which can give them a competitive edge.

With 3D printing, auto parts can be created with intricate designs and detailed features that are not possible with other manufacturing methods.

Saving Money on Inventory and Stock

Another way in which 3D printing saves money is in the area of inventory. With traditional manufacturing, automotive companies have to order large quantities of parts in advance in case they are needed. This can tie up a lot of cash in inventory.

With 3D printing, however, parts can be produced on-demand, as and when they are needed. This reduces the need for large quantities of parts to be held in stock, freeing up funds for other purposes.

3D Printing Saves Money on Shipping Costs for the Automotive Industry

3D printing technology is being used by the automotive industry to save money on shipping costs, especially with current supply chain issues. This technology is allowing automakers to print parts and components on-demand, which reduces the need for inventory and warehouse space or being reliant on suppliers who may not have the parts available to ship in a timely manner.

In addition, 3D printing can help automotive companies to be more responsive to changes in customer demand. Rather than having to wait for parts to be shipped from suppliers, companies can produce parts in-house using 3D printers. This allows them to quickly adapt to changes in the market and better meet customer needs.

The Future of 3D Printing in the Automotive Industry

3D technology is continually evolving, and the automotive industry is always looking for ways to take advantage of new developments. For example, 3D scanning and printing technology is becoming more affordable and accessible, which could lead to more widespread use of these technologies in the automotive industry.

3D printing can be used to create vehicles that are easier to assemble, which can reduce production costs and can be used to create cars that are more durable and have a longer lifespan, as well as create car parts with improved functionality, such as parts that are better able to withstand wear and tear.

The future of 3D printing in the automotive industry is exciting. With new developments in 3D technology, the possibilities are endless. We can expect to see more widespread use of 3D printing in the automotive industry in the years to come, and we are excited to see where they take it!

Ultimaker 3D Printers in the Automotive Industry

Ultimaker 3D printers are being used more and more in the automotive industry. This means that companies can create better prototypes and parts in less time and at a lower cost.

The flexibility of Ultimaker 3D printers also means that they can be used to create parts for a wide range of vehicles. from cars and trucks to motorcycles and boats. This makes them a valuable tool for companies that produce a limited run or custom vehicles.

For more information on Ultimaker, materials or other 3D printing questions, please visit our website at shop3duniverse.com or email us at info@3duniverse.org!