Next-Level Production: Combining 3D Printing with Thermoforming

October 04, 2023

3D Printing and Thermoforming are both powerful technologies for digital fabrication. But the greatest benefits are achieved when these two technologies are combined.

3D printing provides an excellent means for rapid prototyping and design iteration, but when it comes time to start scaling up production, this technology may prove to be too slow for practical use.

Thermoforming technology can provide a much more efficient way of scaling up production, but it requires the use of high-quality templates for creating the end-products.

By using 3D printing to create the templates and then using thermoforming technology to rapidly produce copies from those templates, you can benefit from the key advantages of both technologies.

But which type of 3D printing works best for creating those templates? In this article and the videos contained herein, we'll explore those options and discuss the pros and cons of each.

Video: Thermoforming and filament 3D printing (FDM)

In this video, Mayku colleague Agustín Arroyo explores the benefits of using filament 3D printing (FDM) to create thermoforming templates or tools that can be used on both vacuum forming and pressure forming machines.

Discover design, manufacturing and material use tips to make the best out of both technologies.

Video: Thermoforming and resin 3D printing (SLA)

In this video, Mayku colleague Agustín Arroyo explores the benefits of using resin 3D printing (SLA) to create high-detail thermoforming templates or tools that can be used on both vacuum forming and pressure forming machines.

Discover design, manufacturing and material use tips to make the best out of both technologies.

Video: Thermoforming and SLS 3D printing

In this video, Mayku team member Agustín Arroyo explores the benefits of using SLS 3D printing (Powder Bed Fusion 3D printing) to create resistant thermoforming templates or tools that can be used on both vacuum forming and pressure forming machines.

Discover design, manufacturing and material use tips to make the best out of both technologies.

Video: FDM vs SLA vs SLS 3D printing in thermoforming

In this video, Mayku colleague Agustín Arroyo compares the benefits of FDM, SLA and SLS 3D printing when it comes to manufacturing thermoforming templates or tools.

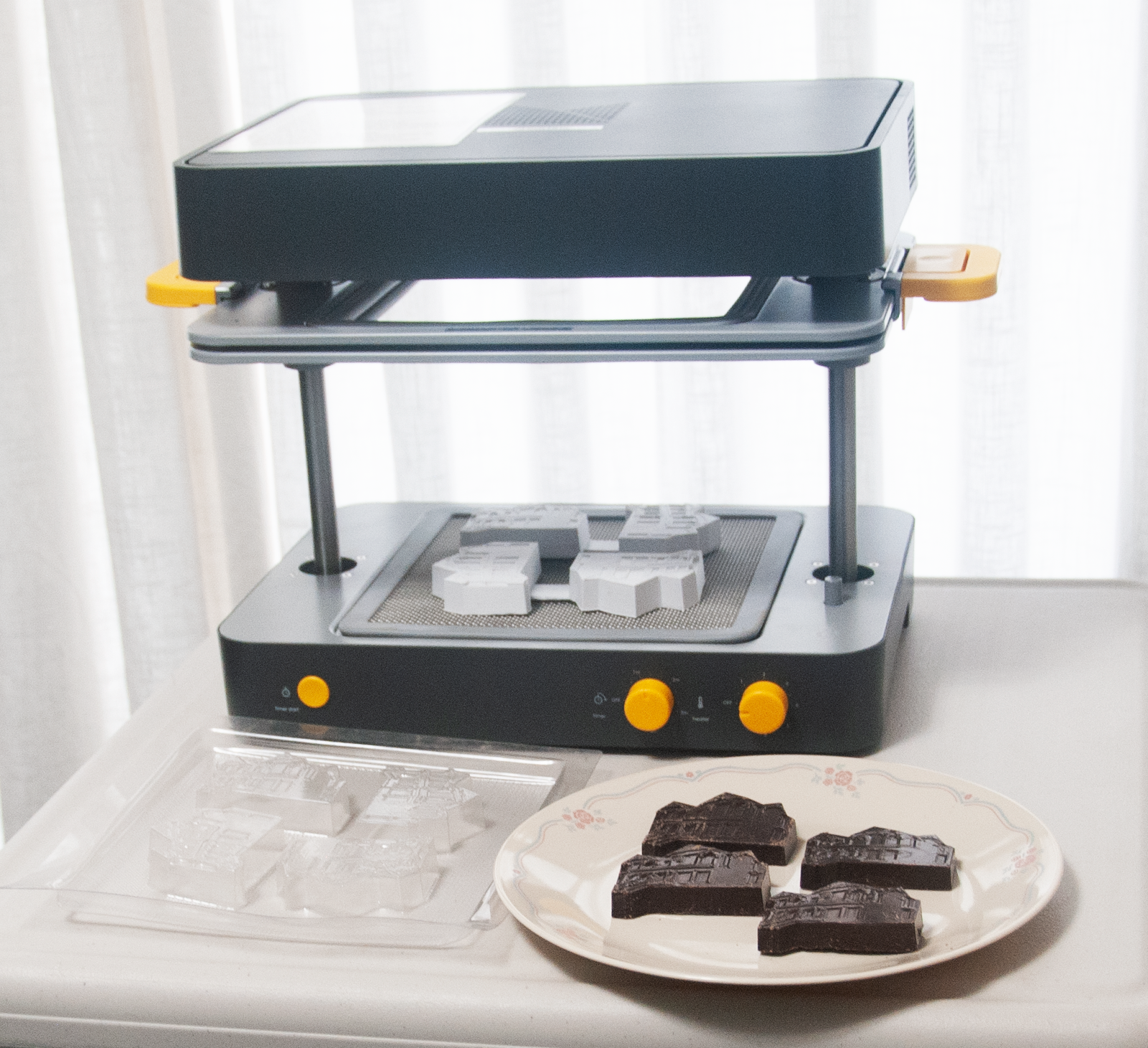

Learn More About the Mayku Multiplier

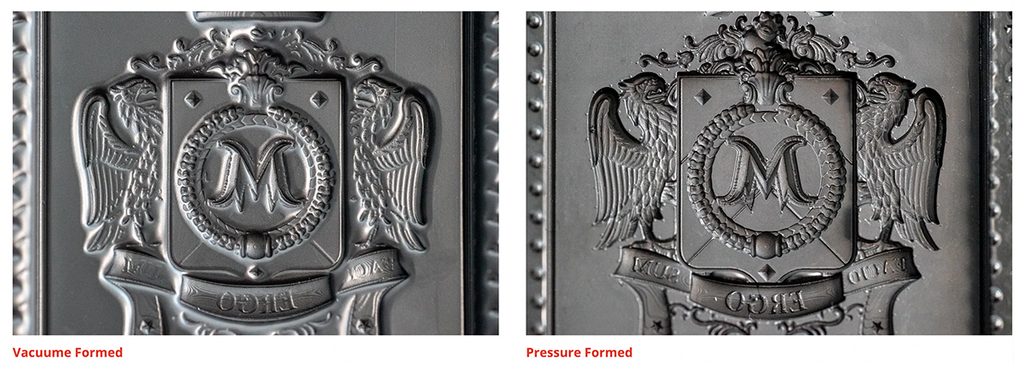

The Multiplier is a desktop pressure former that can achieve sub-one-micron resolution in sheet thicknesses of up to 5mm. Combined with high- resolution 3D printing, it can achieve injection mold- like quality parts right from the desktop in a matter of minutes.

Benefits:

- Create injection mold like quality parts

- Replicate 3D prints at sub-one micron level

- Work with factory materials between 0.5mm and 5mm thick

- Simple to set up and operate

- Replicate 3D printed parts in minutes

Unlike traditional forming, the patented pressure forming method applies consistent pressure across the entire mold, resulting in flawless reproduction of even the most intricate designs.

To learn more about the Mayku Multiplier, please visit our shop at shop3duniverse.com! And as always, please feel free to reach out if you have any questions. You can reach us at info@3duniverse.org or call us at 800-689-4344. You can also click here to schedule a free 30-minute Zoom consultation.